The Trend of 3-side Seal Bags in 2026

Anna_Yu

The Trend of 3-side Seal Bags in 2026

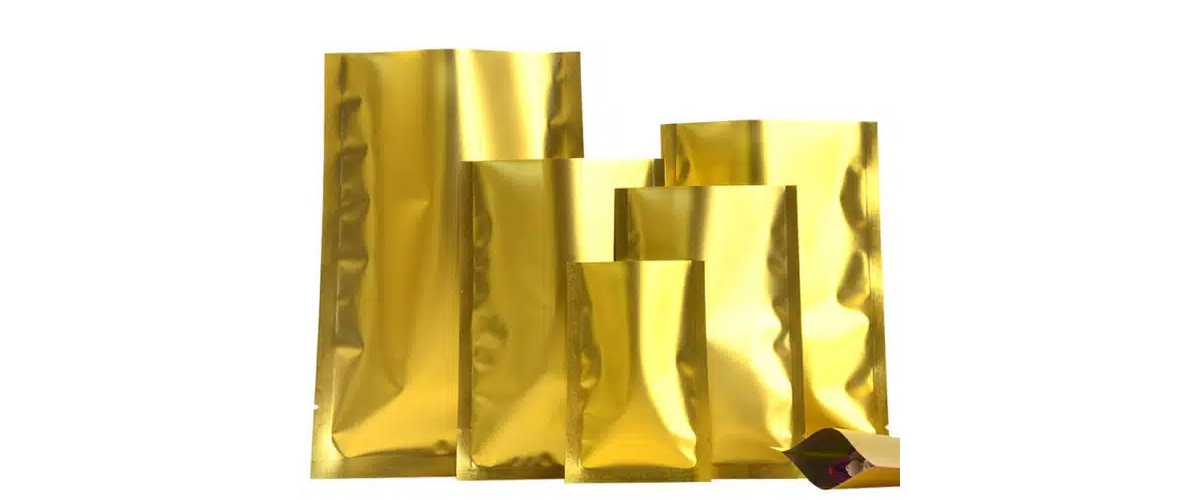

As the global packaging industry continues to evolve, 3-side seal bags are emerging as one of the most cost-effective and versatile flexible packaging formats heading into 2026. Driven by rising raw material costs, sustainability pressure, and the need for efficient mass production, brands across food, pharmaceutical, personal care, and industrial sectors are reassessing their packaging choices. In this context, 3-side seal bags stand out for their simple structure, excellent sealing performance, and broad application adaptability.

From single-serve sachets to medical packaging and frozen foods, the demand for lightweight, flat, and easy-to-produce packaging formats continues to grow. Compared with more complex bag types such as stand-up pouches or flat bottom bags, 3-side seal bags offer clear advantages in manufacturing speed, material utilization, and transportation efficiency. At the same time, improvements in barrier films, printing technology, and customization options are enabling 3-side seal bags to move beyond basic packaging and into more premium, branded applications.

Looking toward 2026, the trend of 3-side seal bags is not merely about cost reduction—it reflects a broader shift toward practicality, efficiency, and scalability in flexible packaging. This article will provide a comprehensive overview of what 3-side seal bags are, how they are structured, their key features, cost-saving advantages, and the industries that are driving their growing adoption.

What is a 3-side seal bag?

A 3-side seal bag is a type of flexible packaging pouch that is sealed on three sides—left, right, and bottom—while the top side remains open for filling. After the product is inserted, the top side is sealed, completing the package.

This bag format is typically produced from roll stock film and formed using high-speed automatic packaging machines. Because of its flat profile and straightforward construction, the 3-side seal bag is one of the most widely used pouch styles in global packaging markets.

Key characteristics of a 3-side seal bag include:

- Flat, rectangular shape

- Minimal material usage

- High sealing reliability

- Compatibility with both manual and automated filling

In 2026, 3-side seal bags continue to be favored for single-use, portion-controlled, and high-volume products, especially where cost efficiency is a priority.

What is the structure of a 3-side seal bag?

The structure of a 3-side seal bag is simple but highly functional. It usually consists of multi-layer laminated films, each layer serving a specific purpose.

Typical layer structure

-

Outer layer (PET / BOPP / Paper)

Provides mechanical strength, printability, and visual appeal. -

Middle barrier layer (Aluminum foil / Metallized film / EVOH / Nylon)

Protects the contents from oxygen, moisture, light, and odors. -

Inner sealing layer (PE / CPP / RCPP)

Ensures food safety, heat seal strength, and compatibility with filling equipment.

This laminated structure allows 3-side seal bags to meet different barrier and durability requirements depending on the product.

Structural advantages

Because all three sealed edges are created during the forming process:

- Seal strength is uniform

- Leak risk is minimized

- Production consistency is high

This structure is particularly suitable for powders, liquids, granules, and semi-solid products.

What are the features of a 3-side seal bag?

The popularity of 3-side seal bags in 2026 is driven by a combination of practical and economic features.

High production efficiency

3-side seal bags are easy to manufacture using automated equipment, enabling:

- Faster production cycles

- Lower labor requirements

- Reduced machine setup time

This makes them ideal for large-scale manufacturing.

Flexible customization

Despite their simple form, 3-side seal bags can be customized with:

- Tear notches

- Easy-open designs

- Transparent windows

- High-quality gravure or digital printing

This allows brands to balance functionality with visual appeal.

Excellent sealing performance

Three sealed edges provide:

- Strong containment

- Good leak resistance

- Reliable protection during transport

This is critical for liquids, sauces, and pharmaceutical products.

Lightweight and space-saving

The flat design reduces:

- Packaging weight

- Storage volume

- Transportation costs

These advantages are becoming increasingly important as logistics costs rise.

How do 3-side seal bags reduce costs?

Cost reduction is one of the most compelling reasons why 3-side seal bags are trending toward 2026.

Lower material consumption

Compared with stand-up pouches or gusseted bags:

- Less film is required

- No bottom gusset or complex folds are needed

This directly reduces raw material costs.

Reduced transportation and storage expenses

Flat bags:

- Occupy less space

- Allow more units per carton

- Lower fuel consumption during shipping

These savings accumulate significantly at scale.

Simplified manufacturing process

The straightforward sealing structure:

- Reduces machine complexity

- Lowers maintenance costs

- Minimizes production downtime

This improves overall operational efficiency.

Lower tooling and development costs

For new product launches or promotional packaging:

- 3-side seal bags require minimal tooling

- Design changes are easier and cheaper

This makes them ideal for fast-moving consumer goods.

What are the application areas of 3-side seal bags?

In 2026, 3-side seal bags are used across a wide range of industries due to their adaptability.

Food and beverage industry

- Sauces and condiments

- Snacks and confectionery

- Frozen foods

- Coffee and powdered beverages

Pharmaceutical and medical industry

- Powdered medicines

- Medical devices

- Diagnostic kits

Personal care and cosmetics

- Sample sachets

- Single-use skincare products

- Hair treatment packs

Household and industrial products

- Detergents and cleaning agents

- Chemical powders

- Agricultural products

The versatility of 3-side seal bags ensures their continued relevance across multiple sectors.

FAQ

Are 3-side seal bags suitable for liquids?

Yes. With proper material selection and sealing strength, they are widely used for sauces, oils, and liquid concentrates.

Can 3-side seal bags be made recyclable?

Yes. Mono-material PE or PP structures are increasingly used to improve recyclability.

Are 3-side seal bags cheaper than stand-up pouches?

In most cases, yes. They require less material and simpler manufacturing processes.

Can high-quality printing be applied to 3-side seal bags?

Absolutely. Gravure and digital printing both work well for this bag type.

Conclusion

As we approach 2026, 3-side seal bags are proving to be a strategic packaging solution for brands seeking efficiency, flexibility, and cost control. Their simple structure, strong sealing performance, and broad application range make them especially suitable for high-volume and single-serve products. With ongoing improvements in materials, sustainability, and printing technology, 3-side seal bags are no longer just a basic packaging option—they are a smart, future-ready choice in modern flexible packaging.