Custom-printed Sachet Roll Stock Film for High-quality Flexible Printed Packaging

Anna_Yu

Custom-printed Sachet Roll Stock Film for High-quality Flexible Printed Packaging

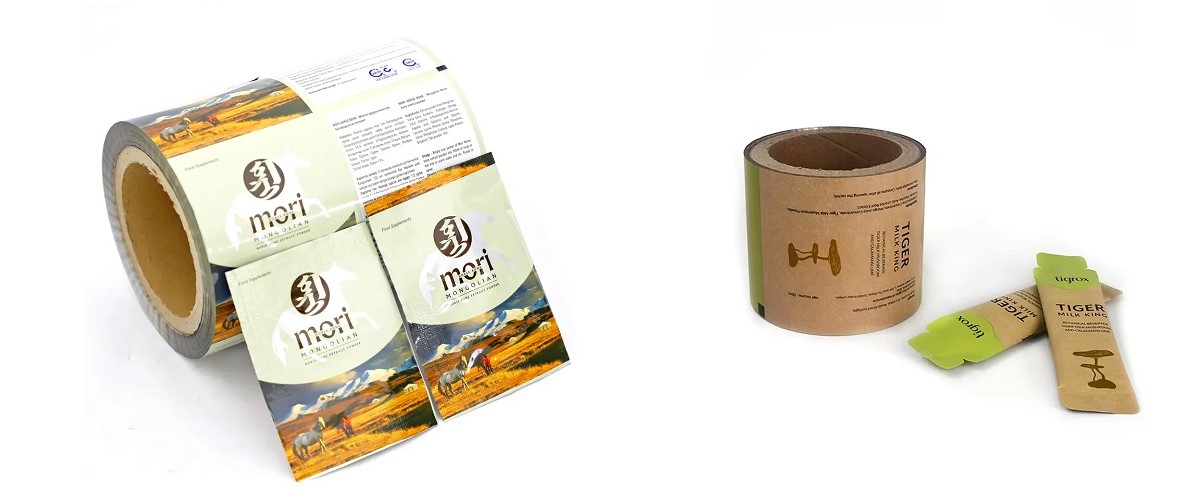

In today’s fast-moving consumer markets, packaging is no longer just a protective layer—it has become a critical part of how products are produced, presented, and perceived. One packaging format that quietly supports millions of products every day is custom-printed sachet roll stock film. From instant coffee and seasoning powders to cosmetics samples and pharmaceutical sachets, roll stock film makes high-speed, high-volume, and cost-efficient packaging possible.

As brands push for faster launches, flexible production, and stronger shelf impact, sachet roll stock film has emerged as a strategic solution. Unlike pre-made sachets, roll stock film allows manufacturers to form, fill, and seal packaging in one continuous process. This not only improves production efficiency but also offers greater flexibility in design, materials, and customization. Even the smallest sachet can now carry sharp graphics, precise information, and brand personality.

At the same time, consumer expectations have changed. Convenience, hygiene, portion control, and sustainability all influence purchasing decisions. Sachet roll stock film must therefore balance multiple requirements: barrier protection, sealing performance, print quality, machine compatibility, and cost control. Achieving this balance requires thoughtful material selection and advanced printing technology.

In this article, I’ll walk you through a clear and practical explanation of custom-printed sachet roll stock film. We’ll look at what it is, what materials are used, how those materials perform, which industries rely on it, and why so many brands continue to choose this flexible packaging solution.

What Is Sachet Roll Stock Film?

Sachet roll stock film is a type of flexible packaging material supplied in rolls, designed for use on form-fill-seal (FFS) machines. Instead of buying pre-made sachets, manufacturers use roll stock film to produce sachets directly during the filling process.

The process is simple in concept but highly efficient in execution. The film is unwound from a roll, formed into individual sachets, filled with product, and sealed—all in one continuous production line. This method allows for extremely high output while maintaining consistent quality and precise portion control.

Custom-printed sachet roll stock film is tailored to specific needs, including:

- Product type (powder, liquid, paste, granule)

- Required shelf life and barrier level

- Filling speed and sealing conditions

- Branding, regulatory, and language requirements

Because sachets are usually small, every millimeter of film matters. The roll stock film must perform reliably on machines, protect the product inside, and clearly communicate brand and product information within a limited space.

What Are the Materials Used in Sachet Roll Stock Film?

Sachet roll stock film is typically made from multi-layer laminated structures, with each layer serving a specific function. The combination of materials determines the final performance of the sachet.

Common Outer Layer Materials

PET (Polyester)

PET is widely used as the outer layer because of its strength, dimensional stability, and excellent printability. It provides a smooth surface for high-quality graphics and protects inner layers from mechanical damage.

BOPP (Biaxially Oriented Polypropylene)

BOPP offers good stiffness, clarity, and cost efficiency. It is often used for dry products where moderate barrier protection is sufficient.

Barrier Layer Materials

Aluminum Foil

Aluminum foil provides an almost complete barrier against oxygen, moisture, and light. It is ideal for products that are highly sensitive, such as pharmaceuticals and nutritional powders.

Metallized Films (VMPET, VMCPP)

Metallized films offer enhanced barrier performance with lower cost and weight compared to aluminum foil, making them a popular choice for food and personal care sachets.

EVOH (Ethylene Vinyl Alcohol)

EVOH delivers excellent oxygen barrier properties and is often used in structures designed for improved recyclability.

Sealant Layer Materials

PE (Polyethylene)

PE is commonly used for its strong heat-sealing properties and moisture resistance, especially for liquid and semi-liquid sachets.

CPP (Cast Polypropylene)

CPP provides stable sealing performance and flexibility, making it suitable for high-speed packaging lines.

Adhesives and Printing Inks

Food-grade adhesives bond the layers together, while certified inks ensure safe and high-quality printing. These components must comply with food-contact and safety regulations.

What Are the Characteristics of Sachet Roll Stock Film Made of These Materials?

The performance of sachet roll stock film depends on how well its materials work together. Several key characteristics define high-quality film.

Strong Barrier Protection

Sachet roll stock film protects products from oxygen, moisture, light, and external contamination. This is essential for preserving flavor, aroma, effectiveness, and shelf life, especially in single-use formats.

Reliable Sealing Performance

Consistent and strong seals prevent leakage and contamination. Sachet films are engineered to seal quickly and evenly on automated machines, even at high speeds.

Mechanical Durability

Despite their small size, sachets must withstand filling pressure, transportation, and handling. The film must resist punctures, tearing, and seal failure.

Excellent Print Quality

High-resolution printing allows clear text, vibrant colors, and accurate branding. This is especially important for regulatory information and brand recognition.

Machine Compatibility

Roll stock film is designed to run smoothly on FFS equipment, with stable friction, accurate registration, and minimal waste.

Which Industries Need to Use Sachet Roll Stock Film?

Sachet roll stock film is widely used across many industries because of its efficiency and flexibility.

Food and Beverage Industry

Single-serve sugar, salt, seasoning, instant coffee, sauces, and beverage powders rely heavily on sachet packaging for portion control and hygiene.

Pharmaceutical and Healthcare Industry

Powdered medicines, oral rehydration salts, supplements, and diagnostic products require precise dosing and high barrier protection.

Cosmetics and Personal Care Industry

Shampoos, lotions, creams, serums, and sample products often use sachets for promotions, travel, and trial use.

Household and Industrial Products

Detergents, cleaning agents, lubricants, and chemical additives are frequently packaged in sachets for controlled application.

Nutritional and Functional Products

Protein powders, vitamins, probiotics, and energy supplements benefit from sachet packaging that ensures freshness and accurate serving sizes.

What Are the Advantages of Sachet Roll Stock Film?

Custom-printed sachet roll stock film offers several important advantages for brands and manufacturers.

High Production Efficiency

Roll stock film supports continuous, high-speed production, reducing labor costs and increasing output consistency.

Cost Control

Compared to pre-made sachets, roll stock film reduces material waste, transportation costs, and storage space requirements.

Flexible Customization

Designs can be easily adjusted for different markets, languages, or promotions without changing the basic packaging structure.

Strong Branding Potential

High-quality printing ensures that even small sachets can deliver strong brand visibility and clear product messaging.

Sustainability Opportunities

Lightweight films reduce material usage, and newer mono-material or recyclable structures help improve environmental performance.

FAQ

Is sachet roll stock film suitable for liquid products?

Yes. With the right material structure and sealing design, sachet roll stock film is widely used for liquids and semi-liquids.

Can sachet roll stock film be customized for different machines?

Yes. Films are engineered to match specific form-fill-seal machine requirements.

Is aluminum foil always necessary?

No. Metallized films or EVOH-based structures can provide sufficient barrier performance for many products.

Is custom-printed sachet film food-safe?

Yes, when produced with certified materials, inks, and adhesives that meet food-contact regulations.

Conclusion

Custom-printed sachet roll stock film plays a vital role in modern flexible packaging. By combining efficient production, reliable protection, and strong branding in one solution, it supports a wide range of industries and applications. Understanding the materials, characteristics, and advantages of sachet roll stock film allows brands to make smarter packaging choices that improve product performance, consumer trust, and long-term competitiveness.