Detailed Explanation of BOPP Film and CPP Film

Anna_Yu

Detailed Explanation of BOPP Film and CPP Film

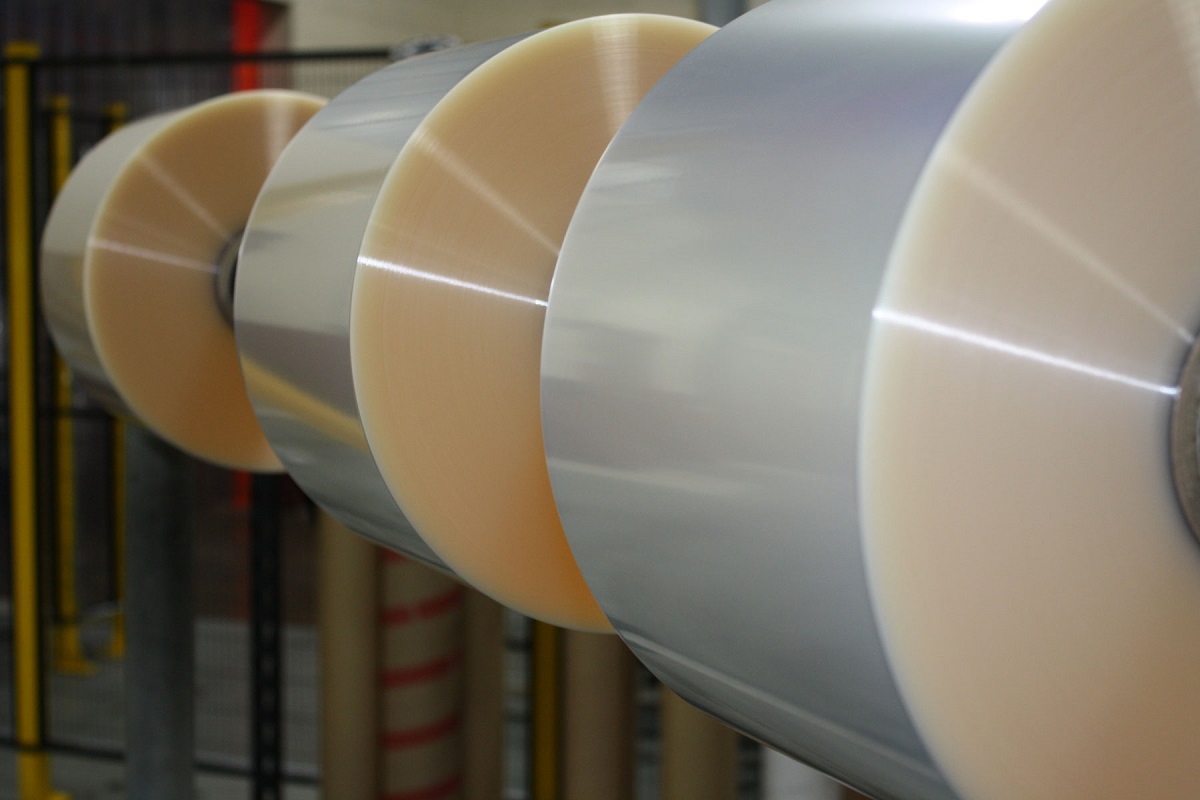

Biaxially Oriented Polypropylene (BOPP) film and Cast Polypropylene (CPP) film are two of the most widely used materials in modern flexible packaging. Their rise is closely linked to global demand for lightweight, strong, economical, and high-performance packaging solutions. While both films are polypropylene-based, their properties, production methods, and ideal applications differ significantly, making them suitable for a wide range of industries—from food packaging to pharmaceuticals to industrial uses.

Understanding the characteristics, strengths, and limitations of BOPP and CPP films is essential for businesses seeking to optimize packaging performance, enhance product shelf life, reduce material costs, and improve sustainability. With packaging technology evolving rapidly, choosing the right film directly influences product freshness, clarity, barrier strength, shelf appeal, and consumer satisfaction. This article provides a comprehensive 360-degree explanation of BOPP and CPP films: what they are, how they differ, where they are used, and what the future holds for these two cornerstone materials in the flexible packaging industry.

1. What Are BOPP Film and CPP Film?

BOPP Film (Biaxially Oriented Polypropylene Film)

BOPP film is a polypropylene film stretched in both the machine direction (MD) and transverse direction (TD). This biaxial orientation significantly enhances its mechanical strength, clarity, stiffness, and barrier properties.

Key characteristics of BOPP film include:

- Excellent clarity and gloss

- Superior tensile strength

- Good moisture barrier performance

- High printability and surface smoothness

- High stiffness and rigidity

- Widely used for snack packaging, labels, lamination, and wrap-around packaging

CPP Film (Cast Polypropylene Film)

CPP film is produced through a cast extrusion process without biaxial stretching. This results in a softer, more flexible film with high heat-seal strength.

Key characteristics of CPP film include:

- High flexibility

- Excellent sealing properties

- Good puncture and tear resistance

- Suitable for retort and hot-fill applications (in special grades)

- Often used as the sealing layer in laminated structures

Why They Are Both Important

Even though both films are types of polypropylene, their roles are different:

- BOPP = appearance, stiffness, print quality, shelf appeal

- CPP = sealing, flexibility, durability

Together, they complement each other in multilayer laminated packaging structures.

2. What Are the Differences Between Them?

Although BOPP and CPP films share polypropylene as their base material, their production methods and final properties vary dramatically. Below is a detailed comparison:

1. Production Method

- BOPP: Produced by stretching the film in two directions → gives higher strength and stiffness.

- CPP: Produced by cast extrusion without stretching → results in soft, flexible film.

2. Mechanical Strength

- BOPP: High tensile strength, high stiffness.

- CPP: Lower stiffness but better impact and tear resistance.

3. Sealability

- BOPP: Generally poor sealability unless coated.

- CPP: Excellent natural heat-seal ability.

4. Transparency and Appearance

Both films can be clear, but:

- BOPP: Better clarity and gloss; used where shelf appeal is important.

- CPP: Slightly softer look, depending on grade.

5. Barrier Properties

- BOPP: Good moisture barrier; moderate oxygen barrier.

- CPP: Lower moisture barrier but good for aroma and flavor retention when laminated.

6. Temperature Resistance

- BOPP: Limited heat resistance; shrinks under high temperatures.

- CPP: Superior high-temperature resistance (in retort-grade CPP).

7. Typical Applications

- BOPP: Food wrappers, snack packaging, labels, tobacco packaging, lamination.

- CPP: Hot filling, retort pouches, bakery packaging, lamination sealing layers.

Comparison Table

| Feature | BOPP Film | CPP Film |

|---|---|---|

| Production | Biaxially stretched | Cast, non-oriented |

| Stiffness | High | Low |

| Sealability | Low → needs coating | Excellent |

| Transparency | Very high | High |

| Moisture Barrier | High | Medium |

| Heat Resistance | Medium | High (retort grades) |

| Flexibility | Low | High |

| Main Function | Printability, appearance | Seal strength, durability |

3. What Are Their Respective Uses?

Both BOPP and CPP films play essential roles in flexible packaging, but their functional strengths lead to different ideal applications.

BOPP Film Uses

Because of its clarity, strength, and print performance, BOPP is widely used in applications requiring brand visibility and product protection:

1. Food Packaging

- Snack foods (chips, biscuits, nuts)

- Confectionery wrappers

- Instant noodles

- Frozen foods (outer layer)

2. Labels and Branding

- Wrap-around labels for beverages

- In-mold labels

- Pressure-sensitive labels

3. Laminated Packaging

Often used as the outer printing layer due to excellent clarity and printability.

4. Industrial Uses

- Overwrap film

- Stationery packaging

- Gift wrap film

CPP Film Uses

CPP is primarily used in applications requiring sealability, strength, and heat resistance:

1. Food Packaging

- Bakery items (bread, snacks)

- Retort pouches (for high-temperature sterilization)

- Frozen food packaging

- Hot-fill food products

2. Laminated Structures

CPP often functions as the inner seal layer in multi-layer packaging.

3. Medical and Pharmaceutical Packaging

- Sterilization pouches

- Medical equipment wrapping

4. Industrial Uses

- Textile packaging

- Lamination seal films

- Twist wrap grade (for candy wrappers)

4. Which Industries Need to Use Them?

Because they are versatile and cost-effective, BOPP and CPP films are used across many sectors. Below are the industries that rely most heavily on these films:

Industries Using BOPP Film

-

Food & Snacks Industry

High clarity and excellent printability make BOPP ideal for branding and packaging dry foods. -

Beverage Industry

Wrap-around labels for water bottles, juice containers, etc. -

Pharmaceutical Industry

Blister pack overwraps, medical labels. -

Personal Care & Cosmetic Industry

Sachets, pouches, outer wraps. -

E-Commerce & Retail

Product display and protective wrapping.

Industries Using CPP Film

-

Retort and High-Temperature Food Industry

Used for ready-to-eat meals requiring sterilization. -

Fresh Food & Frozen Food Industry

Flexible, strong, and durable for cold environments. -

Baked Goods Industry

CPP’s soft and transparent appearance is suitable for bread packaging. -

Pharmaceutical Industry

Sterilization-resistant medical packaging. -

Household & Industrial Applications

Heavy-duty packaging requiring tear resistance.

5. What Are Their Future Trends?

As technology and sustainability become increasingly important, BOPP and CPP films are undergoing significant innovation. Future trends include:

1. Monomaterial Packaging Structures

Brands worldwide are shifting to 100% polypropylene packaging using combinations of BOPP + CPP to improve recyclability.

2. High-Barrier BOPP and CPP Films

New barrier coatings (EVOH, ALOX, SiOX) are being used to replace aluminum foil in certain applications.

3. PCR (Post-Consumer Recycled) PP Films

Development of films using recycled polypropylene to reduce carbon footprints.

4. Biodegradable PP Alternatives

Research is ongoing to develop PP-like materials with compostable properties.

5. Digital Printing Compatibility

Future BOPP film types will be optimized for:

- Inkjet printing

- Digital printing

- High-resolution graphic applications

6. Thinner and Stronger Films

Lightweighting reduces material cost and environmental impact.

7. Improved Heat Resistance for CPP

Enhanced CPP grades for higher retort temperatures and improved stability.

Conclusion

BOPP film and CPP film form the backbone of the modern flexible packaging industry. While both originate from polypropylene, their different manufacturing processes result in unique characteristics that serve distinct but complementary roles. BOPP excels in clarity, strength, and print performance, making it ideal for branding and shelf visibility. CPP shines in flexibility, sealability, and heat resistance, making it essential for sealing layers, retort applications, and durable packaging.

As sustainability demands increase, the trend toward monomaterial PP packaging combining BOPP and CPP will continue to rise. Whether for food, pharmaceuticals, cosmetics, or industrial products, understanding the strengths and limitations of these films enables businesses to make smarter packaging decisions that balance performance, cost, sustainability, and visual appeal.

FAQ

1. Is BOPP better than CPP?

Not necessarily. BOPP is better for stiffness and printability, while CPP is better for sealing and flexibility. Their functions complement each other.

2. Can BOPP and CPP be recycled together?

Yes — when used in monomaterial PP structures, they are easier to recycle.

3. Is CPP suitable for high-temperature sterilization?

Yes, retort-grade CPP can withstand high temperatures up to 121°C.

4. Why is BOPP used for snack packaging?

Because of its excellent barrier properties, high clarity, and suitability for high-quality printing.

5. Can CPP be printed on directly?

Yes, but its printability is generally lower than BOPP, so it's often laminated with a BOPP outer layer.