Detailed Guide to Marshmallow Packaging

Anna_Yu

Detailed Guide to Marshmallow Packaging

Marshmallows are one of the most popular confectionery products worldwide, widely used in snacks, desserts, beverages, baking, and seasonal gift products. Their soft texture, high sugar content, and moisture-sensitive structure make marshmallows especially vulnerable to environmental factors such as humidity, oxygen, temperature fluctuations, and physical compression. Without proper packaging, marshmallows can quickly become sticky, hardened, deformed, or contaminated—significantly reducing product quality and consumer satisfaction.

As global demand for packaged confectionery continues to grow, marshmallow brands are facing increasing pressure to deliver consistent quality, extended shelf life, attractive appearance, and efficient distribution. Packaging is no longer a simple protective layer; it has become a strategic tool for freshness preservation, brand differentiation, regulatory compliance, and logistics optimization.

Traditional paper bags, cardboard boxes, and simple plastic wraps often fail to meet modern retail and export requirements. In contrast, flexible packaging offers superior moisture control, enhanced barrier performance, lightweight transportation advantages, and extensive customization options. From pillow bags and stand-up pouches to premium flat bottom packaging with resealable features, flexible packaging enables marshmallow brands to protect product integrity while strengthening shelf presence.

This detailed guide explores marshmallow packaging by analyzing suitable flexible packaging formats, material selection, barrier properties, custom features, and the key factors affecting shelf life, branding, and distribution success.

1. What Types of Flexible Packaging Are Best for Marshmallow Products?

The ideal packaging format depends on product size, portioning strategy, sales channel, and brand positioning.

Pillow Bags

Pillow bags are widely used for:

- Mass-market marshmallow products

- Family-size and bulk packaging

- High-speed automated production

They offer cost efficiency and excellent filling compatibility.

Stand-Up Pouches (Doypacks)

Stand-up pouches are suitable for:

- Premium marshmallow products

- Flavored or themed collections

- Retail and e-commerce sales

Their upright display improves shelf visibility and branding opportunities.

Flat Bottom Bags

Flat bottom bags are often selected for:

- Gift sets and seasonal packaging

- Premium confectionery lines

They provide superior stability and a high-end appearance.

Vacuum and Modified Atmosphere Pouches

In some applications, vacuum or MAP packaging is used to:

- Reduce oxygen exposure

- Improve hygiene

- Extend shelf life

However, pressure control is necessary to prevent deformation.

2. How Does Packaging Material Affect Marshmallow Freshness and Texture?

Material selection directly influences marshmallow quality during storage and transportation.

Moisture Sensitivity Management

Marshmallows require balanced humidity:

- Excess moisture causes stickiness and melting

- Low humidity leads to hardening and cracking

Proper materials help maintain internal moisture equilibrium.

Structural Protection

Soft marshmallows are easily deformed. Packaging materials must provide sufficient stiffness and puncture resistance.

Oxygen Exposure Control

Oxygen accelerates:

- Flavor degradation

- Color fading

- Microbial activity

High-barrier materials help slow oxidation processes.

Temperature Stability

Some materials offer better resistance to temperature variations, helping preserve texture in warm climates.

3. Which Barrier Properties Are Most Important for Marshmallow Packaging?

Barrier performance determines shelf stability and visual appeal.

Moisture Barrier (MVTR)

Moisture Vapor Transmission Rate (MVTR) is critical for marshmallow packaging. Low MVTR films prevent moisture exchange with the environment.

Oxygen Barrier (OTR)

Low Oxygen Transmission Rate (OTR) helps maintain flavor and appearance.

Light Protection

Light exposure can discolor marshmallows and degrade flavorings. Metallized layers reduce UV penetration.

Odor and Contamination Resistance

High-barrier laminates prevent absorption of external odors and airborne contaminants.

4. What Custom Features Should You Include in Marshmallow Flexible Packaging?

Customization improves functionality and brand recognition.

Resealable Zippers

Zippers support:

- Multi-use consumption

- Moisture control after opening

- Reduced food waste

Easy-Tear Openings

Tear notches enhance consumer convenience and minimize packaging damage.

Transparent Windows (Optional)

Windows allow consumers to view product shape and color, but must be carefully sized to avoid moisture exposure.

Premium Printing and Finishes

Matte coatings, soft-touch finishes, and spot UV effects elevate perceived product value.

Anti-Stick Inner Coatings

Specialized inner layers help reduce sugar adhesion and product sticking.

5. Marshmallow Packaging Guide: Key Factors for Shelf Life, Branding, and Distribution

Effective marshmallow packaging strategies require holistic planning.

Shelf-Life Requirements

Most marshmallow products require 6–12 months of shelf life, while export products may require 12–18 months.

Distribution Conditions

Packaging must withstand:

- Long-distance transport

- High humidity environments

- Stacking pressure in warehouses

Cost vs. Performance Balance

Metallized films often provide sufficient protection for mainstream products, while foil laminates serve premium and export needs.

Sustainability Trends

Growing demand for:

- Recyclable mono-material packaging

- Reduced plastic thickness

- Eco-friendly inks

Is influencing material selection.

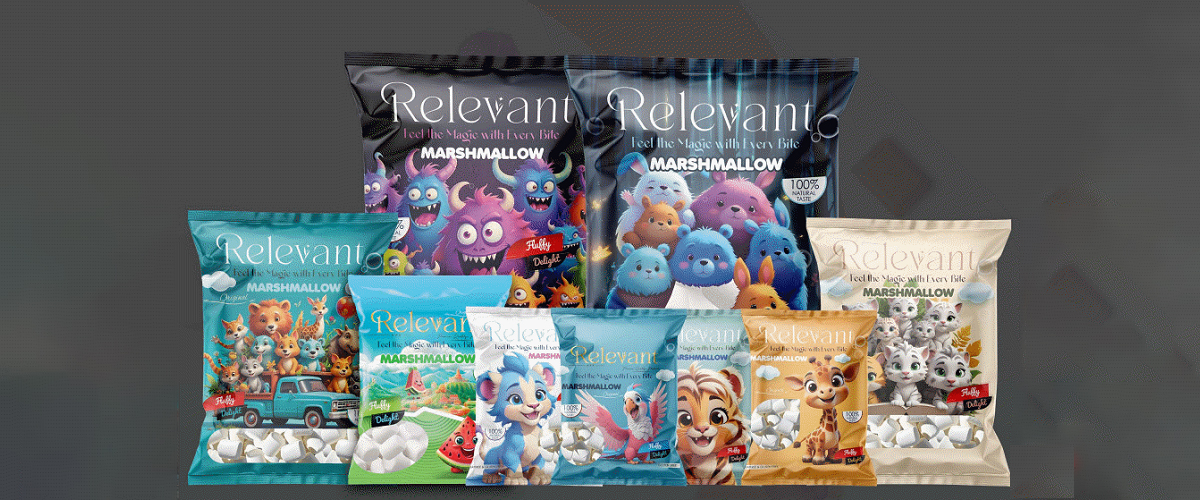

Brand Storytelling

Packaging design communicates:

- Fun and playful brand personality

- Quality positioning

- Seasonal themes and licensing partnerships

Transforming packaging into a marketing asset.

Material Structure Recommendations for Marshmallow Packaging

| Product Type | Recommended Structure | Key Benefit |

|---|---|---|

| Mass-market marshmallows | BOPP/CPP | Cost efficiency and moisture control |

| Premium products | PET/VMPET/PE | Enhanced barrier and shelf appeal |

| Export packaging | PET/AL/PE | Maximum protection |

| Gift packaging | PET/VMPET/PE | Visual impact and durability |

| Sustainable line | Mono PE | Recyclability |

FAQ

What is the best packaging for soft marshmallows?

High-moisture-barrier pillow bags or stand-up pouches with resealable closures.

Do marshmallows need high oxygen barriers?

Moderate oxygen barriers are recommended to preserve flavor and color.

Are transparent windows suitable for marshmallow packaging?

Yes, when properly designed to limit moisture exposure.

Is flexible packaging suitable for premium marshmallow brands?

Absolutely. Flexible packaging supports high-end finishes and creative designs.

Conclusion

Effective marshmallow packaging is essential for preserving softness, preventing stickiness, and ensuring consistent product quality throughout the supply chain. By selecting appropriate bag formats, material structures, barrier properties, and functional features, marshmallow brands can extend shelf life, strengthen brand identity, and optimize distribution efficiency. In a competitive confectionery market, well-designed flexible packaging is not merely protection—it is a powerful driver of commercial success.