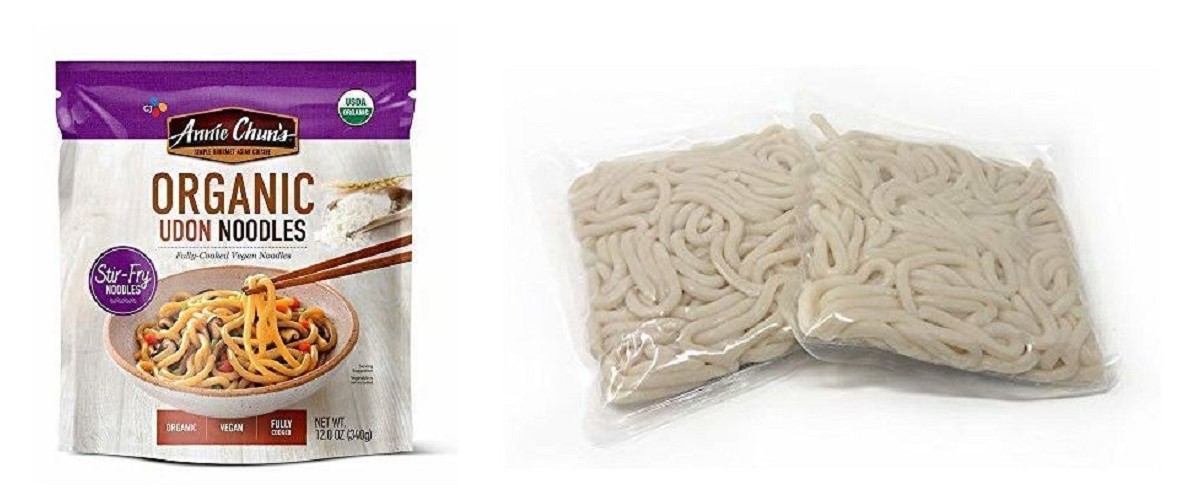

Flexible Packaging Suitable for Storing Udon Noodles

Anna_Yu

Flexible Packaging Suitable for Storing Udon Noodles

Udon noodles are a staple food product with strong regional identity and growing global demand. Whether sold as fresh udon, semi-dried udon, dried udon, or ready-to-cook noodle kits, udon noodles present unique packaging challenges due to their sensitivity to moisture, oxygen, contamination, and physical damage. Improper packaging can lead to texture deterioration, mold growth, flavor loss, or shortened shelf life—directly affecting consumer satisfaction and brand credibility.

As udon noodles increasingly enter modern retail, foodservice supply chains, and international export markets, packaging is no longer just a protective layer. It has become a critical factor in freshness preservation, logistics efficiency, regulatory compliance, and brand differentiation. Traditional rigid containers and simple paper wraps are often insufficient to meet these modern requirements.

Flexible packaging has emerged as a highly effective solution for storing and distributing udon noodles. With customizable material structures, superior barrier performance, lightweight transportation advantages, and compatibility with high-speed filling systems, flexible packaging allows udon brands to protect product quality while optimizing cost and shelf presentation.

This article explores flexible packaging suitable for storing udon noodles by examining optimal bag types, freshness and shelf-life protection mechanisms, material selection, essential functional features, and key factors for long-term storage and export success.

1. What Types of Flexible Packaging Are Best for Storing Udon Noodles?

The best flexible packaging format for udon noodles depends on noodle type, moisture content, shelf-life goals, and distribution channel.

Pillow Bags

Pillow bags are commonly used for:

- Fresh and semi-fresh udon noodles

- High-volume retail products

- Automated filling and sealing lines

They are cost-effective and efficient for mass production, especially in domestic markets.

Stand-Up Pouches (Doypacks)

Stand-up pouches are suitable for:

- Dried udon noodles

- Premium and branded udon products

- Export and e-commerce channels

Their upright display improves shelf visibility and brand recognition.

Vacuum Pouches

Vacuum pouches are widely used for:

- Fresh udon noodles

- Refrigerated or chilled distribution

By removing air, vacuum packaging slows microbial growth and extends freshness.

Flat Bottom Bags

Flat bottom bags are often chosen for:

- Premium udon gift sets

- Multi-portion dried udon products

They provide excellent stability and high-end shelf presentation.

2. How Does Flexible Packaging Affect Udon Noodle Freshness and Shelf Life?

Freshness preservation is the primary function of udon noodle packaging.

Moisture Control

Udon noodles are highly sensitive to moisture imbalance:

- Excess moisture encourages mold and spoilage

- Insufficient moisture leads to cracking and texture loss

Proper flexible packaging maintains stable internal humidity.

Oxygen Barrier Performance

Oxygen exposure accelerates:

- Flavor degradation

- Microbial growth in fresh products

High-barrier materials reduce oxygen transmission and extend shelf life.

Contamination Protection

Multi-layer flexible packaging protects udon noodles from:

- External contaminants

- Odor absorption

- Physical handling damage

Ensuring food safety throughout distribution.

Shelf-Life Extension

Depending on product type:

- Fresh udon: days to weeks (with vacuum or MAP)

- Semi-dried udon: several months

- Dried udon: 12–24 months

Flexible packaging can be tailored to meet these requirements.

3. Which Packaging Materials Offer the Best Moisture and Oxygen Protection?

Material selection plays a decisive role in udon noodle storage performance.

Common Materials Used in Udon Flexible Packaging

- PET: Structural strength and excellent print quality

- BOPP: Cost-effective stiffness and clarity

- PE / CPP: Food-safe heat sealing and moisture resistance

- VMPET: Enhanced moisture and oxygen barrier

- Aluminum Foil (AL): Maximum barrier protection

Recommended Material Structures for Udon Noodles

| Udon Type | Recommended Structure | Key Benefit |

|---|---|---|

| Fresh udon | PA/PE | Puncture resistance and seal strength |

| Semi-dried udon | PET/PE | Moisture balance |

| Dried udon | PET/VMPET/PE | Long shelf life |

| Export udon | PET/AL/PE | Maximum protection |

| Sustainable lines | Mono-material PE | Recyclability |

Selecting the right laminate ensures product stability and regulatory compliance.

4. What Packaging Features Are Essential for Udon Noodle Storage and Distribution?

Functional features improve both performance and user experience.

Strong Heat Seals

Reliable sealing prevents:

- Moisture ingress

- Package leakage

- Shelf-life reduction

Especially critical for fresh udon noodles.

Easy-Open Tear Notches

Tear notches enhance convenience and reduce damage during opening.

Vacuum or MAP Compatibility

Vacuum sealing and modified atmosphere packaging (MAP) help:

- Slow spoilage

- Preserve texture

- Improve food safety

Clear Labeling and Compliance Space

Packaging must display:

- Ingredients and allergens

- Storage instructions

- Country-of-origin information

This is particularly important for export markets.

Printing and Branding Options

Flexible packaging supports high-quality printing that reinforces brand identity.

5. Flexible Packaging for Udon Noodles: Key Factors for Long-Term Storage and Export

Successful udon noodle packaging strategies balance protection, cost, and market requirements.

Shelf-Life Expectations

Export-oriented udon products typically require 12–24 months of shelf life for dried formats.

Distribution Environment

Packaging must withstand:

- Temperature variations

- High humidity

- Mechanical stress during transport

Cost vs. Performance Strategy

Metallized films offer cost-effective barrier performance, while foil laminates serve premium and export markets.

Sustainability Considerations

Growing demand for:

- Recyclable mono-material structures

- Reduced plastic usage

- Eco-friendly inks

Influences packaging design decisions.

Brand Differentiation

Packaging design communicates:

- Authentic Japanese identity

- Product quality and craftsmanship

- Modern or traditional brand positioning

Turning packaging into a marketing asset.

FAQ

What is the best packaging for dried udon noodles?

High-barrier stand-up pouches or pillow bags with moisture protection.

Is vacuum packaging necessary for fresh udon noodles?

Yes. Vacuum packaging significantly extends freshness and food safety.

Do udon noodles need aluminum foil packaging?

Foil is recommended for export and long-term storage applications.

Can flexible packaging be customized for small udon brands?

Absolutely. Flexible packaging supports low MOQs and flexible customization.

Conclusion

Flexible packaging suitable for storing udon noodles is essential for preserving freshness, ensuring food safety, and supporting modern distribution and export demands. By selecting the right bag types, material structures, barrier properties, and functional features, udon brands can extend shelf life, reduce waste, and strengthen brand positioning. In a global market that values both tradition and quality, well-designed flexible packaging is a critical foundation for long-term success.