Metallized PP in Flexible Packaging

Anna_Yu

Metallized PP in Flexible Packaging

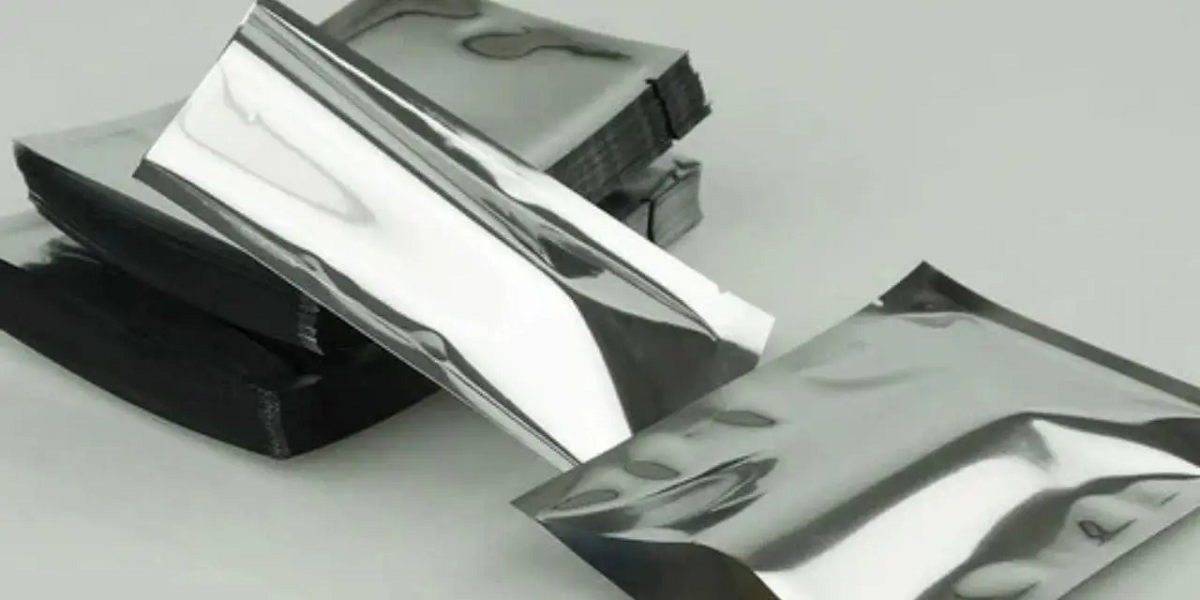

Metallized polypropylene (Metallized PP or MOPP) has become one of the most widely used high-performance materials in modern flexible packaging. As consumer expectations continue to grow—and as brands compete through shelf appeal, barrier protection, and sustainability—metallized PP stands out as a reliable and efficient choice. It offers a balance of durability, visual appeal, and functional performance while remaining compatible with modern high-speed packaging lines. From snacks to dry foods to premium retail products, metallized PP plays an increasingly important role in shaping packaging trends.

The rise in demand for lightweight yet protective packaging materials is closely linked to the need for better moisture resistance, improved barrier properties, extended shelf life, and enhanced brand visibility. Metallized PP addresses these needs at a competitive cost. Its reflective metallic surface elevates product appearance while providing the necessary protection against oxygen, moisture, and external contaminants. As packaging sustainability becomes more important, metallized PP also evolves with recyclable mono-material structures and new lamination technologies.

This detailed guide will explore what metallized PP is, its characteristics, why it has gained popularity in flexible packaging, and how it compares with other packaging materials. By understanding these aspects, you will be better equipped to decide whether metallized PP is the right material for your product and brand.

1. What is metallized PP?

Metallized PP refers to polypropylene film that has been coated with a thin layer of metal—typically aluminum—using a process known as vacuum metallization. In this process, aluminum is evaporated in a vacuum chamber and deposited evenly onto the film’s surface.

This creates a unique hybrid material that combines the strength and flexibility of PP with the functional advantages of aluminum, making it suitable for various food and non-food packaging applications.

Key features of metallized PP

- Thin, uniform metallic coating

- Excellent printability and high surface gloss

- Improved barrier performance compared with standard OPP

- Lightweight yet durable

- Compatible with high-speed packaging lines

- Flexible and highly customizable for different products

Common applications

Metallized PP is widely used for:

- Snack packaging (chips, biscuits, crackers)

- Candy and confectionery wrappers

- Instant food sachets

- Coffee and tea packaging

- Pharmaceutical and cosmetic samples

- Household products

Thanks to its protective qualities and visual appeal, metallized PP works well for products that require both shelf presence and moderate-to-high barrier protection.

2. What are the characteristics of metallized PP?

Metallized PP is valued for its combination of performance and affordability. Its characteristics make it particularly suitable for products requiring barrier protection without the expense of full aluminum foil.

1. Barrier protection

The thin aluminum coating significantly increases the film’s resistance to:

- Moisture (WVTR)

- Oxygen (OTR)

- UV light and external contaminants

While not as strong as aluminum foil, it offers a good balance between barrier performance and flexibility.

2. Excellent visual appeal

Metallized PP has a reflective, eye-catching surface that enhances branding and helps products stand out on retail shelves.

It supports:

- High-resolution gravure or digital printing

- Matte, glossy, or holographic effects

- High-quality metallized shine for premium packaging

3. Heat sealability

Depending on lamination structure, metallized PP can offer very good heat-seal performance, making it ideal for:

- Sachets

- Flow wraps

- Pillow pouches

4. Mechanical strength

PP is naturally:

- Stiff

- Tear-resistant

- Durable

This improves machinability and ensures the packaging maintains a clean shape during transport or display.

5. Lightweight structure

Metallized PP is significantly lighter than aluminum foil laminates, reducing:

- Packaging transportation costs

- Overall material consumption

- Environmental footprint

6. Cost-effectiveness

Metallized PP provides excellent value for brands looking for premium looks and better protection without high material costs.

3. Why is metallized PP popular in flexible packaging?

Metallized PP continues to gain popularity due to its unique blend of performance, appearance, and versatility.

1. Strong barrier protection at a lower cost

Its ability to protect products from moisture, oxygen, and UV light makes it ideal for:

- Snacks

- Dry foods

- Instant products

- Aromatic foods like tea or coffee

It extends shelf life without the cost of full aluminum foil.

2. Exceptional appearance

The shiny metallic finish enhances:

- Retail visibility

- Premium brand identity

- Consumer perception

Many top snack and confectionery brands rely on metallized PP for its attractive presentation.

3. High compatibility with packaging equipment

Metallized PP works well with:

- High-speed flow-wrap machines

- Vertical form-fill-seal machines

- Heat-sealing equipment

its stiffness and surface properties reduce machine downtime.

4. Versatility in laminations

Metallized PP can be laminated with:

- OPP

- CPP

- PET

- PE

- Nylon

This allows packaging engineers to tailor film performance based on product needs.

5. Sustainability potential

With the rise of mono-material packaging, metallized PP becomes even more attractive:

- PP/PP structures are increasingly recyclable

- Brands can reduce multi-material waste

- It supports lighter-weight packaging strategies

6. Cost efficiency

Compared with aluminum foil or high-barrier PET laminates, metallized PP is more economical while still delivering competitive performance.

4. What are the differences between metallized PP and other materials?

To understand the strengths and limitations of metallized PP, it helps to compare it with common packaging materials.

Metallized PP vs. Regular OPP

| Feature | Metallized PP | Regular OPP |

|---|---|---|

| Barrier Level | High | Low |

| Light Protection | Strong | Weak |

| Appearance | Metallic, premium | Transparent |

| Cost | Medium | Low |

| Shelf Life Improvement | Significant | Limited |

Metallized PP outperforms regular OPP in barrier and aesthetics but is more expensive.

Metallized PP vs. Metallized PET

| Feature | Metallized PP | Metallized PET |

|---|---|---|

| Strength | Medium | High |

| Barrier | Moderate–High | High |

| Heat Resistance | Lower | Higher |

| Cost | Lower | Medium |

| Ideal Use | Snacks, candy | Coffee, premium goods |

Metallized PET often provides higher strength and barrier but comes at a higher cost.

Metallized PP vs. Aluminum Foil Laminate

| Feature | Metallized PP | Aluminum Foil |

|---|---|---|

| Flexibility | High | Very low |

| Barrier | Moderate–High | Excellent |

| Cost | Medium | High |

| Weight | Light | Heavy |

| Sustainability | Easier to recycle | Difficult to recycle |

Aluminum foil offers the strongest barrier but is less flexible and significantly more expensive.

Metallized PP vs. Transparent PP (for window packaging)

| Feature | Metallized PP | Clear PP |

|---|---|---|

| Barrier | Higher | Lower |

| Appearance | Metallic | Transparent |

| Consumer Visibility | None | High |

| Common Use | Chips, snacks | Window pouches |

Both materials serve different branding strategies.

FAQ

Q1: Is metallized PP suitable for all food types?

It is ideal for dry and semi-dry foods but is not recommended for products requiring very high barrier like retort foods.

Q2: Can metallized PP be used in sustainable packaging?

Yes. Modern PP/PP laminations make it possible to create recyclable mono-material structures.

Q3: Does metallized PP provide the same barrier as aluminum foil?

No, aluminum foil is superior, but metallized PP offers an excellent cost-to-performance ratio.

Q4: Can metallized PP be printed?

Yes. It supports gravure and digital printing with excellent visual results.

Conclusion

Metallized PP has earned its place as one of the most important materials in flexible packaging because it balances performance, cost, and aesthetics. It provides reliable protection for a wide range of products, enhances shelf impact, and supports high-speed packaging operations. As more brands adopt recyclable packaging and lightweight materials, metallized PP will continue evolving as a key choice in modern packaging design. Whether you’re producing snacks, dry foods, or premium retail items, metallized PP offers an effective, visually appealing, and economically beneficial solution for today’s competitive market.