Packaging Insights: Why Gravure Printing is Crucial

Anna_Yu

Packaging Insights: Why Gravure Printing is Crucial

In today’s increasingly competitive consumer goods market, the visual identity of a product is no longer a secondary consideration—it is a decisive commercial weapon. Packaging has transformed from a simple protective shell into a strategic component of marketing, brand building, and consumer psychology. Among the many printing technologies used in flexible packaging, gravure printing stands out as one of the most powerful, consistent, and commercially impactful methods. Companies across food, beverage, cosmetics, supplements, pet food, and industrial sectors all rely on gravure printing to ensure their packaging captures attention, communicates brand value, and maintains high-quality visual fidelity at scale.

This guide provides a comprehensive analysis of gravure printing: what it is, how it works, why it is essential for custom Mylar bags and other flexible packaging, which industries benefit the most from it, and what the future of gravure technology looks like. Whether you are a brand owner, packaging buyer, or industry professional, understanding the principles and advantages of gravure printing will enable you to make smarter packaging decisions, improve product competitiveness, and build stronger trust among consumers. Let us dive deeper into this high-precision, high-efficiency printing technology and explore why gravure remains the gold standard in modern flexible packaging.

1. What Is Gravure Printing?

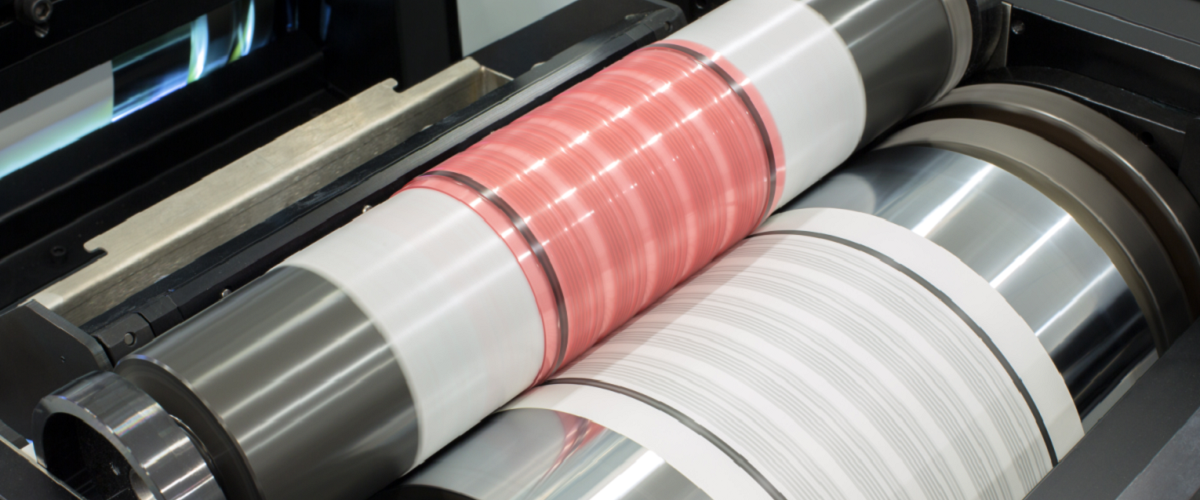

Gravure printing—also known as rotogravure—is a high-precision, high-resolution printing method widely used in flexible packaging, magazines, labels, and decorative laminates. Unlike surface-level printing techniques, gravure printing works by engraving the image directly into a metal cylinder. These engraved cells (also called "cups" or "wells") hold the ink that transfers onto the substrate during the printing process.

Key characteristics of gravure printing:

- Engraved cylinders store ink in recessed cells, enabling extremely fine detail.

- High-speed, continuous roll-to-roll production makes it ideal for large-scale manufacturing.

- Superior ink transfer provides rich, consistent, high-density colors.

- Excellent tonal control, especially for gradients and photographic images.

- Highly durable printing cylinders capable of millions of impressions.

Because of its reliability and unmatched color performance, gravure printing has become the preferred technology in premium flexible packaging production worldwide.

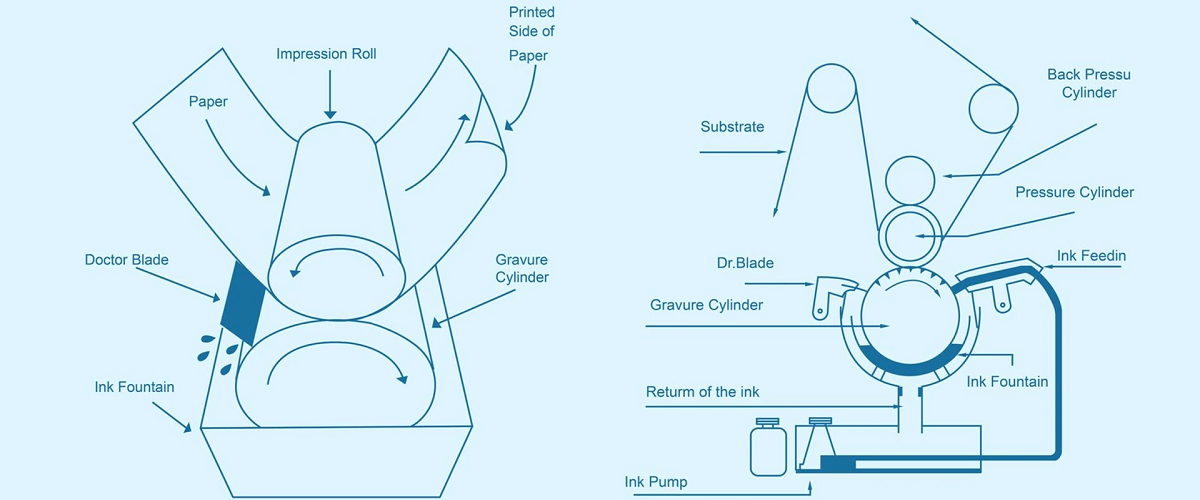

2. How Does It Work?

Gravure printing is both technically sophisticated and mechanically elegant. Although the process involves advanced machinery, its core mechanism can be summarized in a few critical steps:

Step-by-Step Process

-

Cylinder Engraving

A copper-plated printing cylinder is engraved using laser or electromechanical tools. Each engraved cell corresponds to a pixel in the final design, and the depth determines color intensity. -

Ink Application

The entire cylinder is flooded with liquid solvent-based or water-based ink. -

Doctor Blade Cleaning

A steel doctor blade scrapes excess ink from the cylinder surface, leaving ink only inside the recessed cells. -

Substrate Contact

The film (e.g., PET, BOPP, Mylar, nylon) passes between the impression roller and the cylinder. Pressure forces ink from the cells onto the film. -

Drying

Hot air systems rapidly evaporate solvents, locking the ink layer onto the material with high adhesion. -

Rewinding or Lamination

Printed film can be rewound into rolls or laminated with other materials depending on the bag structure.

Why this process matters:

- Unmatched Color Depth – Deep, rich, luxurious tones that digital or flexo often cannot match.

- Sharp Image Quality – Perfect for detailed artwork, small text, metallic effects, and photographic images.

- Very High Speed – Productivity can exceed 350–500 meters per minute.

- Consistent Across Millions of Bags – No fading, drifting, or color misalignment during long runs.

This is why brands that rely on premium packaging—snacks, coffee, beauty products, supplements, pet treats—often select gravure printing as their preferred method.

3. Why Gravure Printing Is Ideal for Custom Mylar Bags?

Mylar bags, especially multi-layer barrier pouches (PET/VMPET/PE, PET/AL/PE, Nylon/PE), require exceptionally high-quality printing due to their premium positioning and high commercial value. Gravure printing meets these needs with precision.

Below are the core reasons gravure printing is the best choice for Mylar packaging:

1. High-Color Density and Premium Visual Appeal

Mylar packaging is often used for:

- Coffee

- Tea

- Supplements

- Powdered products

- Snacks

- Herbal products

- Pet treats

- Cosmetics

These categories rely on visually appealing packaging that stands out. Gravure printing produces:

- Deep blacks

- Vivid reds

- Metallic sheens

- High-contrast photography

- Smooth gradients

This level of detail significantly boosts shelf appeal and brand perception.

2. Extremely Accurate Registration

Multilayer Mylar bags usually require precision alignment between:

- Windows

- Logos

- Resealable zippers

- Puncture tear notches

- Degassing valves

Gravure’s mechanical stability ensures perfect alignment, preventing distorted logos or blurry images.

3. Compatibility with Solvent-Based Inks

Mylar requires inks with high adhesion performance. Gravure printing presses support solvent-based inks that bond well with PET and metallic substrates. This ensures:

- No ink smudging

- High scratch resistance

- No fading under sunlight

- Improved durability

4. Economical for Large-Volume Production

Because gravure cylinders are durable and reusable, it becomes cost-effective for:

- Mid to large production runs

- Private-label manufacturing

- Multi-SKU packaging families

- Seasonal product packaging

For brands planning to scale, gravure is the ideal long-term solution.

4. Which Industries Can Use Gravure Printing?

Gravure printing is versatile and widely adopted across many markets. Below are the major sectors relying on it for flexible packaging.

1. Food Packaging

- Snacks

- Nuts and dried fruits

- Coffee and tea

- Frozen foods

- Spices

- Powdered foods

Gravure ensures vivid images and premium shelf appeal.

2. Beverages

- Instant drink powders

- Juice concentrates

- Tea mixes

- Electrolyte powders

Packages require strong moisture & oxygen protection with high visual impact.

3. Beauty & Cosmetics

- Facial masks

- Serum sample sachets

- Cosmetic refill pouches

- Hair care products

Printed tones must be consistent, luxurious, and clean.

4. Pet Food and Supplements

Pet food brands need beautiful and durable pouches. Gravure helps produce:

- Metallic effects

- Gradient-rich illustrations

- Strong color contrast

5. Pharmaceuticals & Supplements

- Protein powders

- Capsules

- Softgels

- Herbs

High accuracy and cleanliness are essential.

6. Household & Industrial Goods

- Washing liquids

- Detergent powders

- Chemical refills

Durability is crucial, and gravure excels here.

5. What Is the Future of Gravure Printing?

While digital and flexo printing continue to evolve, gravure maintains dominance because of its unmatched consistency and output quality. However, new innovations are shaping the future:

1. Environmentally Friendly Inks

- Water-based gravure inks

- Low-VOC solvents

- Bio-resin technologies

More brands demand sustainable options.

2. Hybrid Digital–Gravure Workflows

Short-run digital + long-run gravure helps brands manage:

- Seasonal packaging

- Limited editions

- Personalized SKUs

3. Smart Registration Systems

AI-driven systems will improve:

- Color accuracy

- Image registration

- Cylinder calibration

4. Recyclable Material Compatibility

Gravure is adapting for:

- Mono-material PE/PE packaging

- Recyclable PP/PP laminates

- Compostable films

5. Faster Manufacturing Speeds

New cylinders, laser systems, and drying units improve speed while reducing energy consumption.

FAQ

Q1: Is gravure printing expensive for small businesses?

Yes, gravure requires an upfront cylinder cost, but for medium to large batches, it becomes the most economical long-term option.

Q2: Can gravure print on recyclable films?

Yes. Modern gravure presses support mono-material PE and PP, which meet recycling standards.

Q3: How long does a cylinder last?

A single cylinder can print millions of impressions, meaning it can be reused across multiple orders or SKUs.

Q4: Does gravure printing fade over time?

No. Gravure inks bond strongly with substrates and retain color even under sunlight and mechanical stress.

Conclusion

Gravure printing remains the gold standard for high-quality Mylar bag and flexible packaging production. With unmatched color depth, precision, and durability, it delivers premium visual effects that elevate brand identity and consumer appeal. As sustainability and digital customization advance, gravure continues to evolve—becoming more efficient, more environmentally conscious, and more aligned with modern brand needs.