Things You Need to Know About Laminated Bags

Anna_Yu

Things You Need to Know About Laminated Bags

Packaging technology is evolving rapidly, and brands today face more competition than ever in retail environments—both on physical shelves and online. With consumer expectations rising, packaging is now not only a protective layer, but also a communication tool, a branding asset, and a silent salesperson. Among numerous packaging solutions, laminated bags have become one of the most versatile and powerful choices. Their popularity has grown as brands seek packaging that combines durability, extended shelf life, high barrier performance, eye-catching aesthetics, and cost-effectiveness.

Laminated bags play an essential role in packaging because they provide multi-layer structural protection that single-layer bags cannot achieve. Through carefully engineered combinations of layers—such as PET, PE, CPP, NY, Foil (ALU), recyclable PE, and other specialty materials—laminated bags deliver advanced performance in moisture resistance, oxygen resistance, aroma retention, strength, and product safety. Whether used for food, pharmaceuticals, cosmetics, pet supplies, specialty chemicals, or agricultural products, laminated bags enable one thing: ensuring products reach the consumer in the best possible condition.

Moreover, laminated bags empower brands to differentiate visually. With modern printing technology, they support glossy finishes, matte finishes, soft-touch, anti-scratch film, metallic effects, holographic patterns, spot UV, and high-definition photographic-level images. This ability to combine visual impact and protective functions has made laminated bags indispensable in today’s value-driven packaging market. As consumer preferences evolve toward sustainability and premium experiences, laminated bags continue to adapt—supporting recyclable structures, biodegradable materials, refill concepts, and lightweight environmental designs.

In the following sections, we will explore everything companies need to know about laminated bags: available types, raw materials, production methods, key benefits, industry impact, and solutions to common packaging challenges. This article will serve as a practical guide for procurement managers, brand owners, packaging distributors, and marketing teams looking to upgrade their packaging strategy and gain a competitive edge.

1. What types of laminated bags are available now?

Modern laminated bags come in an extensive range of structures and formats to match diverse industry needs. Different bag types provide different functionality, shelf-impact, consumer usability, and packaging automation compatibility. Below are the most widely used laminated bag types in the current market:

| Laminated Bag Type | Structural Design | Features | Typical Applications |

|---|---|---|---|

| Stand-up pouch | Bottom gusset expands to stand | Shelf display strength; high branding area | Snacks, nuts, coffee, candy, pet food |

| Flat bottom bag | 5 panels + flat base | Premium appearance; high capacity | Coffee beans, high-end food, supplements |

| 3-side seal pouch | 3 sealed edges | Lightweight; high barrier | Powder products, dried goods, medical items |

| Quad-seal bag | Side panels sealed vertically | Larger capacity; strong shape control | Rice, pet food, cereals, agricultural products |

| Spout pouch | Spout for liquid pouring | Portable; leak-proof | Juice, baby food, sauces, detergents |

| Vacuum pouch | Air removed before sealing | Freshness preservation | Meat, seafood, cheese |

| Retort pouch | Heat-resistant laminated structure | Able to withstand 121°C sterilization | Ready-to-eat meals, wet pet food |

| Zipper pouch | Reusable closure | User-friendly | Daily food, supplements, powders, tea |

| Rollstock film | Laminated sheet on reels | High-speed packaging lines | Industrial packaging automation |

Why so many types exist

Each bag type solves a different combination of needs:

- Shelf visibility

- Transportation and storage efficiency

- Long-term freshness

- User convenience

- Production automation

- Brand premium effect

As product categories expand and consumer expectations increase, laminated bag formats continue to diversify—allowing brands to achieve both functional and marketing goals through packaging.

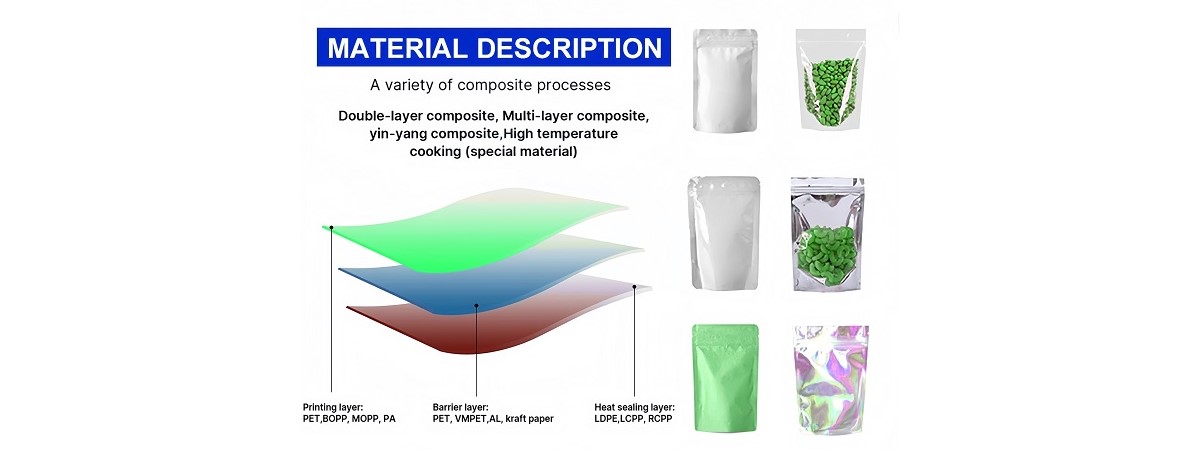

2. What materials are laminated bags made of, and how are they made?

The strength of laminated bags lies in their multilayer combination. Each material layer contributes a unique performance attribute. Below are the most common films used in lamination:

| Material | Strength | Barrier | Heat Resistance | Flexibility | Main Role |

|---|---|---|---|---|---|

| PET | ★★★★ | ★★★ | ★★★ | ★★ | Printing base; stiffness |

| NY (Nylon) | ★★★★★ | ★★★ | ★★★★ | ★★★ | Puncture resistance |

| CPP | ★★★ | ★★ | ★★★★ | ★★★ | Seal strength; retort support |

| PE | ★★ | ★ | ★★ | ★★★★★ | Contact layer; sealing |

| ALU (Aluminum foil) | ★★★★★ | ★★★★★ | ★★★ | ★ | Maximum barrier |

| MPET | ★★★★ | ★★★★ | ★★★ | ★★ | Metallic effect; barrier |

| EVOH | ★★★ | ★★★★★ | ★★★ | ★★ | Extreme oxygen barrier |

| Recyclable PE (Mono-material) | ★★★ | ★★ | ★★ | ★★★★ | Sustainable alternative |

| Biodegradable PLA | ★★ | ★★ | ★ | ★★★ | Compostable eco packaging |

How laminated bags are produced (simplified workflow)

- Film extrusion – Base plastic films are produced

- Printing – Rotogravure or digital printing applied to PET or NY layer

- Lamination – Films bonded layer-to-layer using solvent-based, solventless, or extrusion lamination

- Curing – Adhesive stabilizes; bonding strength developed

- Slitting – Large laminated rolls slit into narrower rolls

- Bag-making process – Pouch form created (side seal, zipper, spout, gusset, etc.)

- Inspection – Seal strength, barrier, appearance, drop resistance, and leak tests

Why lamination is necessary

A single film cannot achieve all the properties required for modern packaging.

Lamination combines the strengths of each material into one unified, functional structure.

3. What are the key functions of laminated bags?

Laminated bags have become a mainstream packaging solution because they provide multiple functions simultaneously. Below are the core performance advantages:

✔ High barrier against oxygen, light, and moisture

Protects food from oxidation, mold growth, and flavor loss — extending shelf life.

✔ Strength + puncture resistance

Protects products during transportation and warehouse handling.

✔ Leakproof and sealing performance

Composite sealing layers prevent spills, aroma escape, or contamination.

✔ Product freshness & flavor preservation

Materials like ALU, EVOH, and high-barrier PET retain fragrance and nutrients.

✔ Attractive branding and shelf display

High-resolution printing and specialty finishes increase consumer appeal.

✔ Cost-efficient compared with rigid packaging

Lower transportation weight and space = reduced logistics cost.

✔ Support for consumer convenience

Zippers, tear notches, windows, spouts, and laser scoring enhance usability.

✔ Flexibility across industries

Suitable for solids, liquids, powders, granular products, frozen goods, hot-fill products, and sterile food.

✔ Sustainability improvements

Lightweight design + recyclable structures = smaller environmental footprint.

4. Why are laminated bags a mainstay of modern packaging?

Global packaging demand has shifted dramatically due to the wide variety of purchasing behaviors and distribution channels. Laminated bags have become indispensable across industries for the following reasons:

🛒 1. Retail competition demands strong visual impact

Products have only 3 to 5 seconds to catch a consumer’s attention on the shelf. Laminated bags allow:

- Vivid printing

- Edge-to-edge graphics

- Matte + gloss dual finishes

- Metallic / holographic effects

📦 2. E-commerce requires high-performance protection

Online sales increase packaging stress due to transportation complexity. Laminated bags:

- Resist drop impact

- Prevent leakage

- Protect aroma against long-distance shipping

🌍 3. Sustainability expectations are rising

Lightweight laminated bags reduce:

- 70% packaging weight vs. rigid plastic

- 65% carbon emissions vs. glass

- 40–60% storage and transit space

💰 4. Brands need cost-optimized packaging

Laminated bags offer a balance of:

✔ Protection

✔ Visual impact

✔ Cost efficiency

Compared to rigid packaging, laminated bags dramatically reduce:

- Storage cost

- Transportation cost

- Packaging waste volume

🔐 5. Food safety and shelf-life performance

Global markets increasingly require:

- Oxygen control

- Moisture control

- Hygiene guarantees

- Tamper-resistance

Laminated structures exceed performance levels achievable by single-layer packaging.

5. What are some common problems in packaging, and how do laminated bags solve these problems?

| Common Packaging Problem | Business Impact | Laminated Bag Solution |

|---|---|---|

| Moisture/oxygen entering | Shorter shelf life | High-barrier laminated layers block gas and humidity |

| Loss of aroma or flavor | Customer dissatisfaction | Aroma retention layers protect freshness |

| Bag tearing during transit | Returns and complaints | Nylon and multi-layer strength prevent rupture |

| Leaks and spills | Logistics failures | Heat-seal PE/CPP layers + reinforced seals |

| Poor printing quality | Weak branding | HD rotogravure + matte/gloss finishing |

| Heavy packaging weight | High shipping cost | Lightweight laminated films reduce mass |

| Disposability concerns | Environmental pressure | Recyclable mono-material PE structures |

| Poor customer experience | Low repurchase rate | Zipper + tear notch + laser score + window |

Why laminated bags continue to dominate the packaging market

- They combine brand value + protection + convenience + sustainability + cost savings

- They evolve continuously as technology advances

- They support customization for every business stage (from startup to global brand)

FAQ

Q1: Are laminated bags safe for direct food contact?

Yes. Food-grade laminated bags use certified layers suitable for direct contact when produced under strict compliance standards.

Q2: Can laminated bags be made eco-friendly?

Yes. Recyclable mono-material PE, biodegradable PLA, and solventless lamination are increasingly available.

Q3: Do laminated bags support small-batch customization?

Yes. Digital printing allows low-MOQ orders without plate cost.

Q4: Which industries use laminated bags the most?

Snacks, coffee, tea, nuts, pet food, cosmetics, supplements, frozen food, agriculture, industrial goods, and pharmaceuticals.

Q5: Can laminated bags be used for high-temperature processing?

Yes—retort pouches and CPP-based laminated structures withstand sterilization up to 121°C.

Conclusion

Laminated bags have become a cornerstone of modern packaging due to their superior blend of barrier protection, durability, branding capacity, convenience, and cost efficiency. They not only protect products across transportation and storage but also help brands stand out visually, communicate value, and deliver a premium customer experience. With sustainability, e-commerce, and product diversification reshaping global markets, laminated bags continue to evolve — adopting recyclable structures, biodegradable materials, smart packaging features, and next-generation printing technologies.

Whether a business is a startup testing a new product or an established brand scaling into international distribution, laminated bags provide a reliable and future-ready packaging solution. Companies that invest in high-quality laminated bags are not just improving packaging — they are strengthening brand positioning, increasing consumer trust, and maximizing long-term market competitiveness.