What Everyone Ought to Know about PE Bags

With the need for better packaging and storage alternatives increasing worldwide, PE has stepped onto the scene as a go-to option instead of rigid packaging and boxes, especially for storing food. But before we go on, what exactly is this material and how can it cater to different packaging needs? To answer this, we need to take a close look at PE.

PE Film: Lightweight, Recyclable & Built to Protect

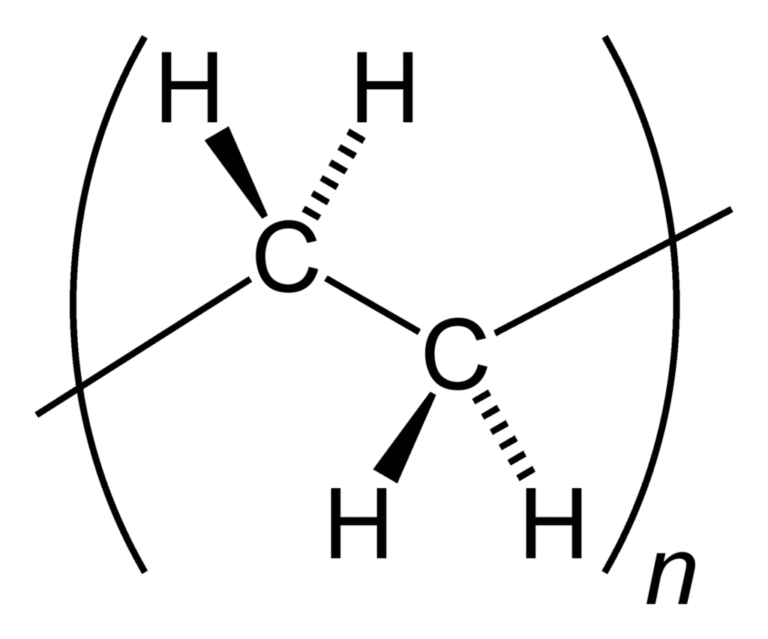

Polyethylene is a popular polymer in the packaging industry and is the most common plastic in use in the world today.

It is available in different forms and is composed of a combination of smaller units (called monomers) of ethylene. PE is classified by its density, with the most common polyethylene types being HDPE, LDPE, and LLDPE.

LLDPE (Linear Low-Density Polyethylene) is defined within a density range of 0.915-0.925g/cm3. It has better tensile strength than the LDPE variant and possesses some favorable qualities like higher impact and puncture

resistance over LDPE. It is popular in the packaging industry and may also be used for cable coverings, toys, buckets, and containers.LLDPE is useful in film applications due to its unique blend of toughness, flexibility, and relative transparency.

PE is made of non-polar, saturated hydrocarbons with high molecular weight. This quality grants it excellent chemical stability, meaning that it is inert to chemical attacks from strong bases and acids.

Discover Our Developer Tools

Food Packaging

Used for snacks, frozen foods, fresh produce, bread, and dairy products. Its moisture-resistant nature keeps food fresh and extends shelf life.

Beverage Packaging

Suitable for liquid liners, pouch films, and secondary packaging like shrink wraps.

Cosmetic Packaging

Common in flexible pouches for lotions, shampoos, and creams, offering durability and spill resistance.

Industrial Goods

Used for heavy-duty sacks, liners, and stretch wraps to protect products like fertilizers, powders, and chemicals during transit.

Client Testimonials

PET+PE

Material Characteristics:

PET offers excellent strength, rigidity, and printability, while PE provides superior heat-sealing properties and moisture resistance. Together, they create durable and visually appealing packaging with a protective inner seal.

Layer Structure:

*Outer Layer: PET for strength, printability, and a glossy finish.

*Inner Layer: PE for moisture resistance and heatsealing.

Applications:

Commonly used for snacks, frozen foods, and lightweight products requiring attractive designs and secure seals.

BOPP+PE

Material Characteristics:

BOPP offers high clarity, durability, and resistance to oils and grease, while PE provides a secure seal and acts as a moisture barrier. This combination is lightweight and highly flexible.

Layer Structure:

*Outer Layer: BOPP for excellent transparency and durability.

*Inner Layer: PE for heat sealing and moisture protection.

Applications:

Ideal for baked goods, confectionery, and fresh produce packaging, where visibility and freshness are key.

Nylon (PA)+PE

Material Characteristics:

Nylon adds superior flexibility, puncture resistance, and durability, while PE ensures moisture resistance and reliable heat sealing. This pairing is perfect for vacuum-sealed and retort packaging.

Layer Structure:

*Outer Layer: Nylon (PA) for flexibility and puncture resistance.

*Inner Layer: PE for heat sealing and moisture protection.

Applications:

Used in vacuum bags, retort pouches, and meat packaging that require robust sealing and flexibility.

Aluminum Foil+PE

Material Characteristics:

Aluminum foil offers unmatched barrier properties against oxygen, light, and moisture, while PE provides a reliable sealing layer. This structure is highly protective and ideal for preserving sensitive products.

Layer Structure:

*Outer Layer:Aluminum Foil for high barrier performance.

*Inner Layer: PE for sealing and additional moisture resistance.

Applications:

Perfect for coffee, pharmaceutical items, and products requiring maximum shelf-life protection.

Metallized Film (VM)+PE

Material Characteristics:

Metallized film is a polymer (such as PET or BOPP) coated with a thin layer of aluminum. While it provides good barrier properties, it is not as effective as aluminum foil in blocking oxygen and moisture but is lighter, more flexible, and cost-efficient.

Layer Structure:

*Outer Layer: Metallized PET (VMPET) or Metallized BOPP (VMBOPP) for barrier properties and visual appeal.

*Inner Layer:PE for heat sealing and moisture resistance.

Applications:

Commonly used for snacks, frozen foods, and lightweight products requiring attractive designs and secure seals.

EVOH+PE

Material Characteristics:

EVOH enhances the oxygen barrier, while PE provides heat sealing and moisture resistance. This combination is excellent for perishable food packaging.

Layer Structure:

*Outer Layer: EVOH for superior oxygen barrier properties.

*Inner Layer: PE for sealing and moisture protection.

Applications:

Widely used for sauces, processed foods, and items needing extended shelf life in controlled environments.