PET Film for Durable, High-Transparency Packaging

Strong, printable, and heat-resistant — PET is the go-to outer layer film for food, pharma, and industrial pouches. Widely recyclable and brand-safe. PET film offers versatile applications in flexible packaging, excelling as an outer layer for printing, a middle layer for structural integrity and barrier properties, and a heat-resistant solution for microwave or oven-ready packaging, ensuring both functionality and visual appeal.

What is PET?

PET, short for polyethylene terephthalate, is a popular type of plastic commonly employed in a variety of industries around the world.

It is a strong, clear, lightweight polymer that is widely utilized in the food industry for storage and transportation. PET is also used as storage to inedible materials like liquid soap, shampoos, and window cleaners, just to name a few.

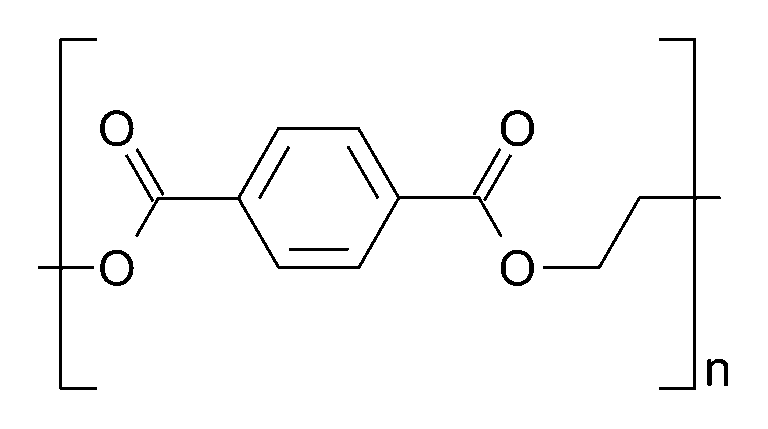

Taking a deeper look at this material, PET at its basic level is formed by a chemical process called esterification. Here, an acid (terephthalic acid) combines with an alcohol (ethylene glycol) at certain defined conditions to form the polyester PET. This material is the most common thermoplastic polymer of the polyester family.

PET has the resin identification number “1”, meaning that it can be recycled repeatedly.

PET is made up of recurring units of the monomer ethylene terephthalate. The hexagonal-shaped object in this structure (called an aromatic ring) gives this polymer its strength and stiffness. This stiffness makes it more resistant to deformation compared to other polymers

PET Film Applications in Flexible Packaging

PET film offers versatile applications in flexible packaging, excelling as an outer layer for printing, a middle layer for structural integrity and barrier properties, and a heat-resistant solution for microwave or oven-ready packaging, ensuring both functionality and visual appeal.

Outer Layer Applications

PET film is often used as the outermost layer in packaging due to its high clarity and excellent heat resistance. Its transparency enhances the visual appeal of the product, while its heat resistance makes it ideal for printing. PET provides a smooth surface for high-quality graphics, ensuring vibrant and detailed designs.

Middle Layer Applications

When used as an intermediate layer, PET enhances the structural integrity and appearance of the package. Its oxygen transmission rate (OTR ≤ 120cm³/(m²∙24h∙0.1Mpa)) improves the overall barrier properties, keeping the contents fresh and protected for longer periods.

Heat Resistance and High-Temperature Applications

Typical structures include PET/High-Density PET or Coated Paper/HSPET, used for direct heating of food items like ready meals.

Specialized Use Cases

Jelly Packaging: PET sheet material is ideal for jelly packaging. For a secure seal, lidding films made from the same PET material are used, ensuring compatibility. High-frequency positron emission tomography (PET) scanning is employed to ensure precise sealing and quality control.